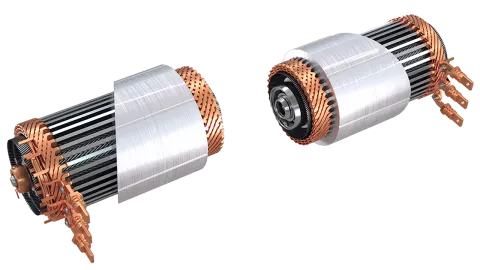

As development timelines for electric drive systems continue to shorten, the complexity of creating and testing e-motor technologies becomes increasingly evident. From Permanent Magnet Synchronous Motors (PMSM) to Asynchronous Motors (ASM) and Electrically Excited Synchronous Motors (EESM), alongside advanced inverter technologies like Silicon Carbide (SiC), the variety of powertrain concepts adds to the challenge.

We offer a comprehensive portfolio of e-motor test systems, software, tools, and processes that enable rapid, high-quality testing and validation of these cutting-edge e-drive systems. With AVL, you can achieve faster time-to-market without compromising on quality.

The e-drive system is pivotal to the satisfaction of both drivers and passengers in electric vehicles (EVs), as it is central to delivering an exhilarating driving experience. Modern e-drive systems are engineered to be compact with high power density, optimized for efficiency, performance, and drivability.

Additionally, these systems must adhere to strict Noise, Vibration, and Harshness (NVH) requirements to ensure a smooth and comfortable ride. Compliance with rigorous Electromagnetic Compatibility (EMC) standards is essential for vehicle safety. Moreover, the robustness of the e-drive system is critical to meeting longevity and durability requirements throughout its operational lifespan.

Developing e-motors with high power density and efficiency is crucial for modern automotive drives. EIt is equally important to ensure first-class driving characteristics in terms of comfort, economy and sportiness. The AVL E-Motor TS™ Performance is designed to unlock the full potential of your e-motor and inverter. Its advanced mechanics and dynamometer design provide reliable testing at high speeds with precise control accuracy in both stationary and dynamic conditions. Our state-of-the-art software tools, including AVL PUMA 2™, CAMEO™, and Indicom, along with the AVL E-Library™, provide comprehensive solutions for tuning, analysis, and validation. Achieve fast, powerful, and reliable test results with our proven software tool chain.

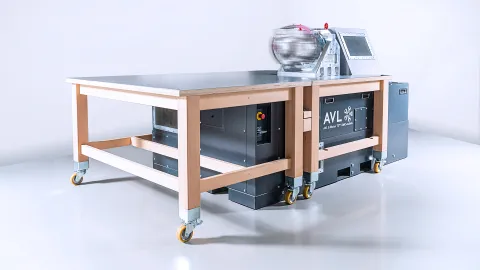

The increasing complexity of noise and sound in modern powertrains requires advanced NVH technology. Our expertise in high-speed applications and NVH testing has led to the development of a comprehensive portfolio of standard NVH test system solutions. The AVL E-Motor TS™ NVH offers customization to meet the specific needs of each customer. We focus on creating development environments that efficiently address NVH challenges with a range of solutions categorized into Premium, Precision, and Efficiency setups. These options ensure that we can meet diverse requirements while increasing development speed and sustainability.

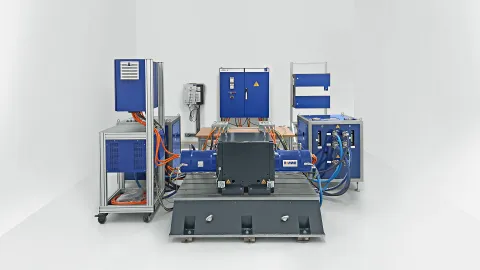

Managing electromagnetic emissions and interference is critical for modern vehicles equipped with advanced communication interfaces. Our solutions comply with the latest EMC standards and allow comprehensive assessment and validation under real-world conditions. Our test solutions provide mobile capabilities for full-load EMC testing in existing chambers, minimizing the need for modifications. This mobility facilitates efficient setup and transfer, while our fixed and modular systems ensure uncompromised torque and speed during testing. Our solutions provide a fully equipped environment for e-motor development, ensuring optimal performance of electronic systems.

Increase the reliability and durability of your electric drive system with AVL E-Motor TS™ Durability. This solution is designed to accelerate time-to-market goals by covering a wide range of assessments, including reliability, availability, maintainability, and durability. It supports environmental testing at extreme temperatures and evaluates accumulated mileage, cold start, warm-up, and production batch tolerance. By enabling reliable production of e-motors without extensive road testing, our innovative procedures accelerate mileage accumulation, reduce overall test time, and lower handling costs.

As the e-mobility market expands, manufacturers face increasing demands for industrialization and production volumes. To meet these demands, reliable and future-proof solutions are essential. We support every project phase, from concept to operation, with a comprehensive production test portfolio. Our solutions include loaded and unloaded end-of-line testing, quality audit and conformity of production testing. This approach ensures robust production processes and high quality standards for all produced e-motors, safeguarding your manufacturing operations and increasing product reliability.

An e-motor testbed must meet many requirements to ensure a fast and reliable test process. Effective testing of units under test across multiple performance levels - such as power, current, voltage, speed, and torque - is essential.

Sophisticated design is crucial for these test systems to accommodate different technologies and performance metrics. To accelerate the development process, it is critical to frontload activities to ensure smooth integration of the e-drive system into the vehicle. The development phases present unique challenges that can be effectively addressed with our comprehensive e-motor testing portfolio. Our solutions are designed to streamline the testing process and improve the overall efficiency of your e-motor development.

Our passion is to tune and optimize our e-motor testbeds, products and software tools and make them perfect not only for e-motor testing but also to push customers developments to get the best e-drive for their electric vehicle. With our wide portfolio existing of Performance, NVH, EMC, Durability, and Production Test Systems we deliver the right basis to reach that goal.”

– Mario Propst, System Line Manager E-Drive, AVL List GmbH

AVL E-Mobility Testing Solutions – Brochure

Tested and Trusted.

AVL E-Motor Testing Solutions – Brochure

Validate e-motors of different types, speeds, and torques.

Success Story – “High Performance at Hitachi Astemo”

AVL Dynamic Torque Analysis – Solution Sheet

Future-proof and reliable e-motor testing.

The best-in-class automation system for e-motor testing.

The perfect hardware for AVL’s leading automation system

AVL’s E-Library is a mindful solution that introduces simplicity when dealing with e-testing complexity, provides a fast track to productivity, and offers reassurance that targets will be met – putting your mind at ease and allowing you to enter the market with full confidence.

AVL CAMEO 5™ unlocks a new maturity level of calibration and validation in automotive software testing.

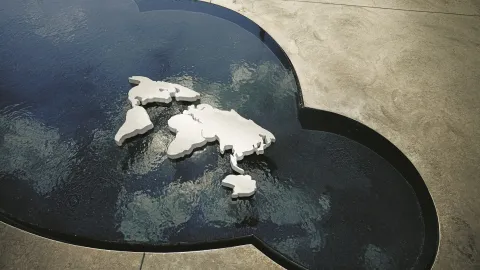

The AVL Customer Services organization consists of more than 700 service- and application engineers worldwide, operating from more than 50 locations. Our global footprint is your local benefit.

Versatile and easy-to-use inverter emulator improves your e-motor and inverter development and testing processes.

We provide comprehensive and advanced e-motor testing solutions designed to ensure precise, efficient, and reliable evaluation of electric drive systems. Our solutions accelerate development, address NVH challenges, and ensure the quality and durability of e-motors.

The Added Value

-

Optimized Testing Efficiency: Our advanced testing systems deliver rapid and accurate evaluation of e-motors, including PMSM, ASM, and EESM, expediting vehicle integration.

-

Enhanced NVH Management: Our customizable NVH testing solutions effectively handle noise and vibration challenges, ensuring a quiet and comfortable driving experience.

-

Superior EMC Compliance: With mobile and fixed testing solutions, we ensure e-motors meet the latest EMC standards and operate reliably within existing communication systems.

-

Advanced Durability Testing: Our Durability system boosts e-motor reliability through extensive environmental and mileage tests, reducing the need for costly road tests.

-

Comprehensive Production Testing: Our testing solutions cover all production phases, from End-of-Line testing to Quality Audits, ensuring manufacturing efficiency and product quality.

Thanks to our global e-drive experts, AVL has a holistic know-how in engineering and testing of modern e-motors and Inverters for any kind of electric vehicles. Many of these experts are located in our affiliates and global tech- and engineering centers for customer support and projects.

15

years of experience with e-motor testbeds

> 300

e-motor test systems in use globally

Complete

portfolio, existing of performance-, NVH-, EMC-, durability- and EOL testbeds

45

Affiliates ensure global support

45

Global Tech- and Engineering centers

AVL RACETECH, the motorsport department of AVL, presents the prototype of an innovative H2 internal combustion engine. The power unit is a compact, hydrogen-powered 2-liter turbo engine, with intelligent water injection, which achieves a totally new performance level. The first racing engine that AVL RACETECH is developing and building in-house.