Enhance the reliability and durability of your electric drive system with the AVL E-Motor TS™ Durability. Our advanced testing solution helps you meet fast time-to-market goals while ensuring top performance.

Our system provides a full suite of assessments, including reliability, availability, maintainability, and durability evaluations. It also supports environmental testing in extreme hot and cold conditions, ensuring your e-motors perform under real-world climate challenges. Additional test capabilities include long-term mileage accumulation testing to measure durability over extended use, cold start and warm-up procedure testing to ensure efficient operation at different temperatures, and accurate monitoring of production batch tolerances to maintain manufacturing quality.

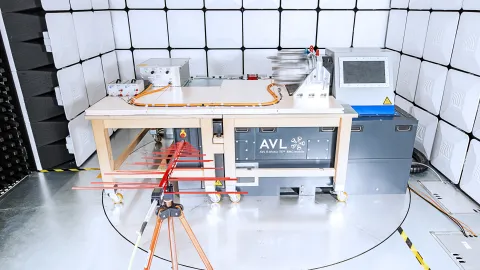

The AVL E-Motor TS™ Durability system revolutionizes the testing process by enabling the simultaneous evaluation of two units under test in parallel. This innovative approach significantly enhances efficiency and reduces overall testing time.

Key features of the AVL E-Motor TS™ Durability system include:

- Intelligent AVL PUMA 2™ automation system with machine learning technology

- Highly accurate battery emulator

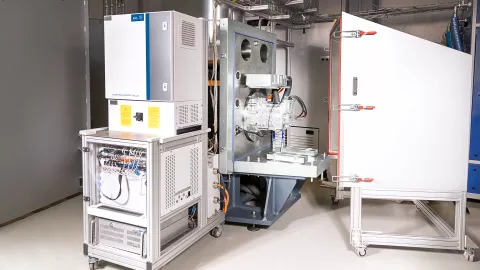

- Precious coolant conditioning system and optional climatic chamber

- Mechanics with frame, intermediate bearing and mounting systems

- High frequency AVL X-ion™ power analyzer

- Baseline measurement for temperature, voltage, and current measurements

- Testbed safety monitoring system

By incorporating these advanced features, the AVL E-Motor TS™ Durability system enables manufacturers to conduct thorough and efficient testing of electric motors.

|

AI-Powered Automation System

Detect and react to trends, deviations, or any kind of anomaly by continuously validating data.

Future-Proof Test System

Proven mechanics for UUT speeds of up to 25,000 rpm.

Modular Approach

Upgradeability with coolant conditioning, climate chamber, more powerful DC supply, power analyzer, and torque flange.

Cost-Efficient Test System

Unlike an e-motor testbed where only one e-motor is tested, our back-to-back testbed tests two e-motors simultaneously.

The AVL E-Motor TS™ Durability provides advanced testing solutions, ensuring long-term reliability and performance of electric motors. It combines innovative simulation and testing methodologies to accelerate the development process while minimizing risks and failures.

– Mario Propst, System Line Manager E-Drive, AVL List GmbH

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL E-Motor Testing Solutions – Brochure

Validate e-motors of different types, speeds, and torques.

Success Story – “High Performance at Hitachi Astemo”

AVL E-Motor Testing Solutions – Application Sheet

An overview of our solutions on 2 pages.

Customer Use Cases

Compiled key use cases of the Universal Inverter.