The e-drive system is pivotal to the satisfaction of both drivers and passengers in electric vehicles (EVs), as it is central to delivering an exhilarating driving experience. Modern e-drive systems are engineered to be compact with high power density, optimized for efficiency, performance, and drivability.

Additionally, these systems must adhere to strict Noise, Vibration, and Harshness (NVH) requirements to ensure a smooth and comfortable ride. Compliance with rigorous Electromagnetic Compatibility (EMC) standards is essential for vehicle safety. Moreover, the robustness of the e-drive system is critical to meeting longevity and durability requirements throughout its operational lifespan.

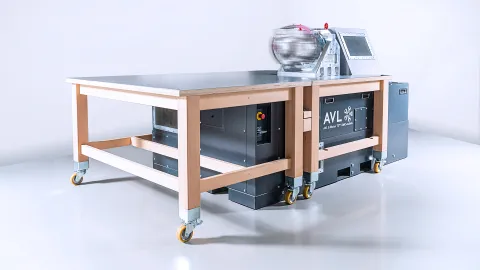

An e-motor testbed must meet many requirements to ensure a fast and reliable test process. Effective testing of units under test across multiple performance levels - such as power, current, voltage, speed, and torque - is essential. Our best-in-class automation and control system offers outstanding user experience, easy customization, and unique features like high-precision speed and position control. AVL PUMA 2™ Machine Learning allows detecting anomalies in the setup, e.g., increased vibrations, at an early stage, preventing potential damage to the unit under test and saving valuable time.

Dedicated to fine-tuning our e-motor testbeds, products, and software tools, we ensure they excel in e-motor testing and support our customers in developing best e-drive systems. With a comprehensive portfolio that includes Performance, NVH, EMC, Durability, and Production Test Systems, we provide the foundation to achieve superior e-drive performance.”

– Alban Hemery, Dept. Manager, AVL List GmbH

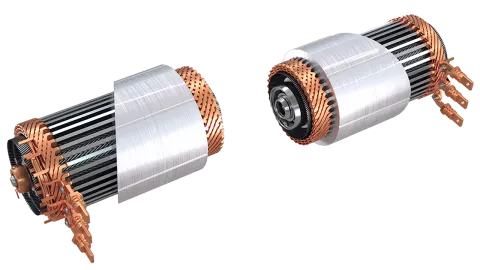

We provide comprehensive and advanced e-motor testing solutions designed to ensure precise, efficient, and reliable evaluation of electric drive systems. Our solutions accelerate development, and ensure the quality and durability of e-motors. Our advanced testing systems deliver rapid and accurate evaluation of e-motors, including PMSM, ASM, and EESM.

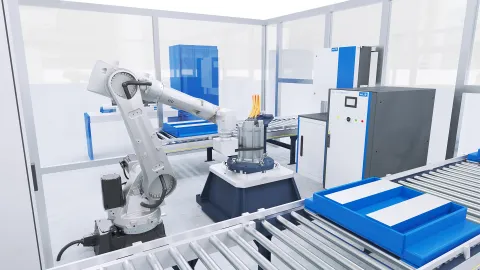

With mobile and fixed testing solutions, we ensure e-motors meet the latest EMC standards and operate reliably within existing communication systems. Our testing solutions cover all production phases, from End-of-Line testing to Quality Audits, ensuring manufacturing efficiency and product quality.

AVL E-Motor Testing Solutions – Brochure

Validate e-motors of different types, speeds, and torques.

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL E-Motor Testing Solutions – Application Sheet

An overview of our solutions on 2 pages.

Success Story – “High Performance at Hitachi Astemo”

AVL Dynamic Torque Analysis – Solution Sheet

Future-proof and reliable e-motor testing.

AVL Test System Automation – Brochure

Tailored Software Solutions for Future-Proof Test Environments.

Presentation – Applications Universal Inverter

Compiled key use cases of the Universal Inverter.

AVL offers comprehensive software solutions to optimize your e-motor testing performance. Our holistic approach combines lab efficiency through automation and test optimization via virtualization for faster results.

The advanced data analytics solution using AI extracts valuable insights from various sources. Additionally, our solutions are designed to seamlessly integrate with your existing systems, ensuring a smooth transition.

This will help you get your products to market faster while ensuring high-quality performance. Learn more about AVL’s approach and explore our software solutions to optimize your e-motor testing process now.

The best-in-class automation system for e-motor testing.

The perfect hardware for AVL’s leading automation system

AVL CAMEO 5™ unlocks a new maturity level of calibration and validation in automotive software testing.

AVL’s E-Library is a mindful solution that introduces simplicity when dealing with e-testing complexity, provides a fast track to productivity, and offers reassurance that targets will be met – putting your mind at ease and allowing you to enter the market with full confidence.

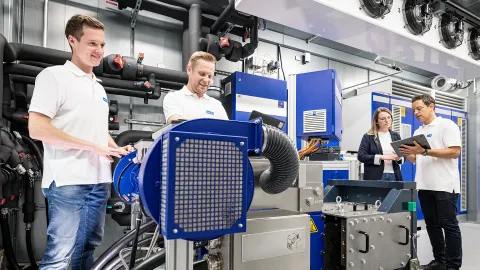

The AVL Customer Services organization consists of more than 700 service- and application engineers worldwide, operating from more than 50 locations. Our global footprint is your local benefit.

Versatile and easy-to-use inverter emulator improves your e-motor and inverter development and testing processes.

DRICON is a flexible, modular robotic solution designed to transform vehicle testing. Our solution covers emissions, durability, and range testing with high precision, consistency, and effortless integration into existing test setups.

AVL’s e-motor testing solutions can handle a variety of e-motor types, including Permanent Magnet Synchronous Motors (PMSM), Asynchronous Motors (ASM), and Externally Excited Synchronous Motors (EESM).

AVL’s e-motor testing systems offer precise, efficient, and reliable evaluation of electric drive systems. They help accelerate development, validate performance, address NVH (Noise, Vibration, and Harshness) challenges, ensure EMC (Electromagnetic Compatibility) compliance, and ensure durability and production quality.

Yes, AVL’s e-motor test systems can be used in various industries beyond automotive. These systems are versatile and can be applied to mobility sectors such as aviation, rail, marine and stationary sector. Additionally, AVL provides specialized test systems for high-performance applications in motorsport. This flexibility makes AVL’s solutions suitable for a wide range of electric motor testing needs across different industries.

AVL provides a comprehensive portfolio of NVH test systems, including customizable solutions to meet specific customer needs. These systems help manage noise and vibration challenges, ensuring a quiet and comfortable driving experience. AVL offers different standardized test system setups: The Premium Setup achieves the lowest noise at high speed, the Efficiency Setup offers the highest modularity, and the Precision Line enables a complete microphone hemisphere without interference from mechanical surfaces, ensuring accurate sound measurements.

AVL’s EMC test solutions comply with the latest standards (CISPR 25 and ISO 11452-2) and allow comprehensive assessment and validation under real-world conditions. They offer both mobile and fixed testing solutions to ensure e-motors meet EMC standards. The standardized Interface with Rohde & Schwarz R&S®ELEKTRA EMC test equipment automation and AVL PUMA™ testbed automation ensures smart and efficient testing in dynamic real driving conditions with realistic results.

AVL’s state-of-the-art software tool chain provides comprehensive solutions for automation, calibration, analysis, and validation. These software products help achieve fast, powerful, and reliable test results, post-processing and optimizing the overall efficiency of e-motor development. Browse here to learn more: AVL PUMA™, AVL CAMEO™, AVL CONCERTO™, AVL IndiCom™, AVL PUMA™ Machine Learning, Testbed.CONNECT™, AVL ISAC™.

Yes, AVL offers a complete production test portfolio, including end-of-line testing (EoL), quality assurance (QA), and conformity of production testing (CoP). These solutions ensure robust production processes and high-quality standards for all produced e-motors.

AVL’s high-speed e-motor test system can handle performance and function tests up to 60,000 rpm (even up to 125.000 rpm for racing applications). These systems provide precise control accuracy in both stationary and dynamic conditions, supporting the development of high-speed e-motors.

Yes, AVL offers advanced climatic chambers specifically designed for e-motor testing. These chambers can simulate a wide range of environmental conditions, from extreme cold (-40° C) to intense heat (up to +150°C) as well as humidity, ensuring that e-motors are thoroughly tested for durability and performance under various scenarios. The test systems are equipped with advanced safety features to handle critical thermal issues and ensure the protection of both the test components and the surrounding facilities.

AVL’s e-motor testbeds are designed to meet various performance levels, including power, current, voltage, speed, and torque. They are optimized for different technologies and performance metrics, ensuring a fast and reliable test process. What makes the AVL test systems unique, are elements like the AVL SPECTRA™ family with latest Sic technology inside for best dyno performance and control capabilities, tools like the Universal Inverter or the Dynamic Torque Sensor, the holistic software-toolchain including the automation software PUMA, that also covers machine learning, and measurement devices such as AVL X-ion power analyzer including e-motor specific applications.

AVL offers modular test systems (containers) that can be easily scaled up. By adding more test modules, you can increase your testing capacity without significant downtime. Another way to maximize testing is the implementation of AVL’s advanced automations systems PUMA or request a consulting by our support team: They provide on-site assistance, training and maintenance to ensure your test systems are always running at optimal capacity.

Thanks to our global e-drive experts, AVL has a holistic know-how in engineering and testing of modern e-motors and Inverters for any kind of electric vehicles. Many of these experts are located in our affiliates and global tech- and engineering centers for customer support and projects.

15

years of experience with e-motor testbeds

> 300

e-motor test systems in use globally

Complete

portfolio, existing of performance-, NVH-, EMC-, durability- and EOL testbeds

45

Affiliates ensure global support

45

Global Tech- and Engineering centers