CO₂ Reduction

Emissions are composed of a variety of gases and particulates that must all be considered in the quest for clean mobility. Greenhouse gases, such as CO₂, CH4 and N2O are known to have a significant influence on climate change and therefore OEMs face tough legislation for its reduction.

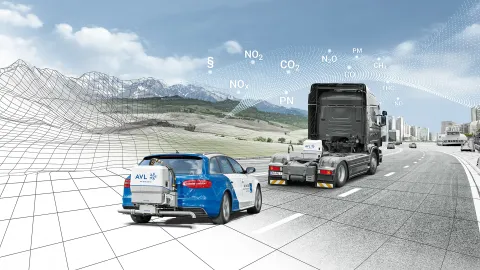

In order to meet these requirements, innovative technologies for reducing (ideally avoiding) and measuring CO₂ are required. This also includes devices for measuring the electrical energy flow of electrified powertrains. In heavy commercial vehicles as used in the transport industry, the CO₂ emissions of diesel engines are verified worldwide under simulated conditions, in real vehicles and on the road. This means that tests, measurements and simulations must take into account the entire vehicle, as well as the entire powertrain.

Dedicated hybrid engines for instance represent a valuable contribution to CO2 reduction. The utilization of the synergies in an electrified powertrain enable to maximize the ICE efficiency up to 45% (BTE, Gasoline Engine, Passenger Car Segment) in stoichiometric operation.

Pollutant Emission

Pollutant emission are a threat to human health, especially in large cities. The threat is made worse by the density of pollutant sources and their proximity to people, making it a local issue that must be solved globally.

In order to meet this challenge , the development effort for effective combustion and aftertreatment systems is constantly increasing. This is largely due to the demands for better performance imposed by emission legislation. New ways must therefore be found to increase system performance while reducing the complexity of development tasks as well as costs and time spans.

Nations around the world have made it their goal to reduce pollutants and greenhouse gas emissions. As a result, the automotive industry is facing increasingly stringent regulations. However, because requirements differ from market to market, OEMs must find solutions that ensure robustness, reliability, cost efficiency and compliance around the world.

We at AVL have all the simulation, engineering, and testing solutions to meet emission legislations worldwide. We offer the right answer for every market and help OEMs achieve CO₂ targets.